Blog

RSS FeedWe get this question a lot. How do you wash a safety vest?

We have outlined a comprehensive guide on how to wash a safety vest, this will help extend the life and retain the effectiveness of your safety vest. Washing a safety vest is essential to maintain its visibility and functionality. Proper care and cleaning can help extend the lifespan of your safety vest, ensuring you stay safe and visible while working or engaging in outdoor activities. Here’s a step-by-step guide on how to wash a safety vest:

Step 1: Begin by Checking the Label

Step 1: Begin by Checking the Label

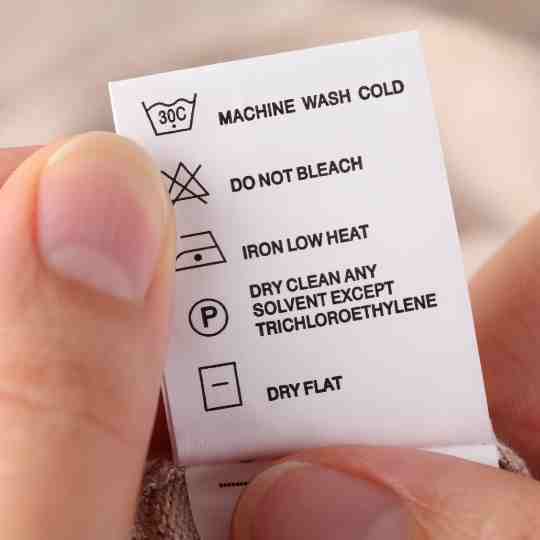

Before washing your safety vest, always check the label for care instructions. Most garments will provide information on the recommended washing method, temperature, and detergent to use. It may also specify whether the vest is machine-washable or if it needs to be hand-washed, and whether it should be tumble dried or air dried.

Step 2: Pre-Treat Stains & Prep for Washing

If your safety vest has any stubborn stains you will want to pre-treat them with a mild detergent or stain remover. You want to be sure the detergent is mild so that it will not cause the fabric to fade. Do not use bleach unless it is specified to do so. Gently rub any stained area with a soft brush or cloth to help work the cleaner into the fabric. This will help remove the stain during the washing process. To prepare your vest for washing you will want to ensure that everything is zipped up, if your vest has Velcro, make sure to close all fasteners, this will prevent the garment from getting torn, frayed or tangled up. If your vest has screen printed or heat pressed logos, it is best to wash the garment inside out in order to preserve the quality of the imprint.

Following the care instructions on the label, wash your safety vest using the appropriate method. If it’s machine-washable, use a gentle cycle with cold or warm water, avoid hot water as it can cause fabric dyes to fade. Cold water is generally the safest option for most safety vests, as it helps preserve the reflective materials and colors. It is always best to wash separately, some high visibility fabrics can be colorfast, and you do not want them to bleed and damage other clothing.

When selecting a detergent, choose one that is gentle and free of bleach, as it can damage the reflective and high visibility materials on the vest. You may also want to use a delicate laundry bag or pillowcase to protect the vest. You should also never use fabric softeners with high visibility apparel, as it can damage the reflective materials.

Step 4: Drying your Safety Vest

Step 4: Drying your Safety Vest

After washing, avoid using a dryer to dry your safety vest, as the high heat can damage the reflective materials and cause colors to fade. Instead, lay the vest flat on a clean, dry surface and allow it to air dry. You can also hang the vest on a clothesline, ensuring that the reflective materials do not touch each other to prevent damage. If the label states that it is safe to tumble dry, make sure that you use the delicate and the lowest heat setting on your dryer.

Step 5: Inspect and Safely Store you Safety Vest

Step 5: Inspect and Safely Store you Safety Vest

Once the vest is completely dry, inspect it for any remaining stains or damage. If necessary, repeat the washing process or spot-treat the stains before storing the vest. When storing, fold the vest gently and keep it in a cool, dry place away from direct sunlight to maintain its color and visibility. If you find that the color has faded or there are any damaged areas, you should consider replacing the vest.

If you are looking for affordable safety vests, we have a huge selection to choose from. We manufacture our own line of sustainable high visibility vests and safety apparel. Many of these options are made using REPREVE® fabrics and we are also authorized dealers for many high quality and trusted safety apparel brands.

Shop All Vests: Vests - Apparel (tsasafety.com

Shop Sustainable Safety Apparel: Sustainable Products (tsasafety.com)

Shop All Safety Apparel: Work Apparel and Safety Clothing Supplier | TSA (tsasafety.com)

We co-founded Transportation Safety Apparel (TSA) in 2003, and it's a quintessential American success story. It all started in an extra bedroom in our South Carolina home, deeply rooted in our family business heritage. John's family had a background running a police, fire, and safety catalog, which also began very modestly from a pawn shop. The knowledge gained through that venture, helped lay the groundwork for TSA.

We co-founded Transportation Safety Apparel (TSA) in 2003, and it's a quintessential American success story. It all started in an extra bedroom in our South Carolina home, deeply rooted in our family business heritage. John's family had a background running a police, fire, and safety catalog, which also began very modestly from a pawn shop. The knowledge gained through that venture, helped lay the groundwork for TSA.

Throughout our journey, we have accomplished significant milestones that have contributed to our success and reputation in the industry. One of the most notable achievements was securing our first major contract with an international waste management company, a partnership that has flourished for nearly two decades. This long-standing relationship is a testament to the quality of our services and the trust we have built with our clients over the years.

We have custom-tailored uniform, safety equipment, and safety apparel programs for numerous companies across various industries. Our clientele spans a wide array of sectors including aviation, public safety, construction, transportation, hospitality, and many more. This diverse client base reflects our ability to cater to the specific needs and requrements of different industries, showcasing our adaptability and expertise in providing tailored solutions.At the core of our business philosophy is a strong commitment to catering to both large and small orders, serving businesses of all sizes as well as individual customers. We take pride in treating each client with equal dedication, regardless of the scale of their order or their organizational size. This dedication to client satisfaction has been integral to our success and has helped us build enduring relationships with a wide range of customers.Another distinctive aspect of TSA is our WBENC certification, highlighting our majority woman-owned status and our commitment to diversity in the workforce. This aligns with our mission to address the needs of businesses with diverse workforces and meet diversity requirements.

Sustainability is another key focus for us. This year, we aim to relocate all manufacturing of our TSA branded items to North America, reducing our carbon footprint by minimizing the travel distance for our goods. Additionally, we've implemented eco-friendly practices in shipping and packaging, such as eliminating single-use plastic and utilizing biodegradable packing materials.

One of our proudest achievements is our sustainable hi-visibility apparel line, using REPREVE® fabric made from recycled bottles. This initiative forms a full circle, as the recycled bottles from waste companies are transformed into protective apparel for the same industry.

We emphasize TSA's unique value proposition: building intimate customer relationships through a deep understanding of their needs and consistent fulfillment of those needs. We prioritize customer intimacy, quality, and competitive pricing, fostering a family-like bond with customers and employees. This approach sets us apart from larger corporations and underpins our ongoing success.